Warehouse Lighting Systems

Ensure that employees can easily locate products and navigate the system safely.

Get in TouchLearn about warehouse Lighting

Warehouse lighting can be placed either within or above a rack system. Having proper lighting ensures that employees can easily locate products and safely navigate the system.

We work with end users, manufacturers, dealers, and contractors to provide a safe, compliant material handling system.

RCS is a woman owned and operated, WBE certified company that provides full project management of warehouse lighting systems, including in-rack, ceiling, and exit/emergency lighting.

We use high quality lighting that is especially effective in a warehouse environment.

RCS Warehouse Lighting System

System Services

RCS is a team of experts that thoroughly understand the requirements of warehouse lighting systems. We ensure this complex process runs smoothly so that your material handling system can be completed on time.

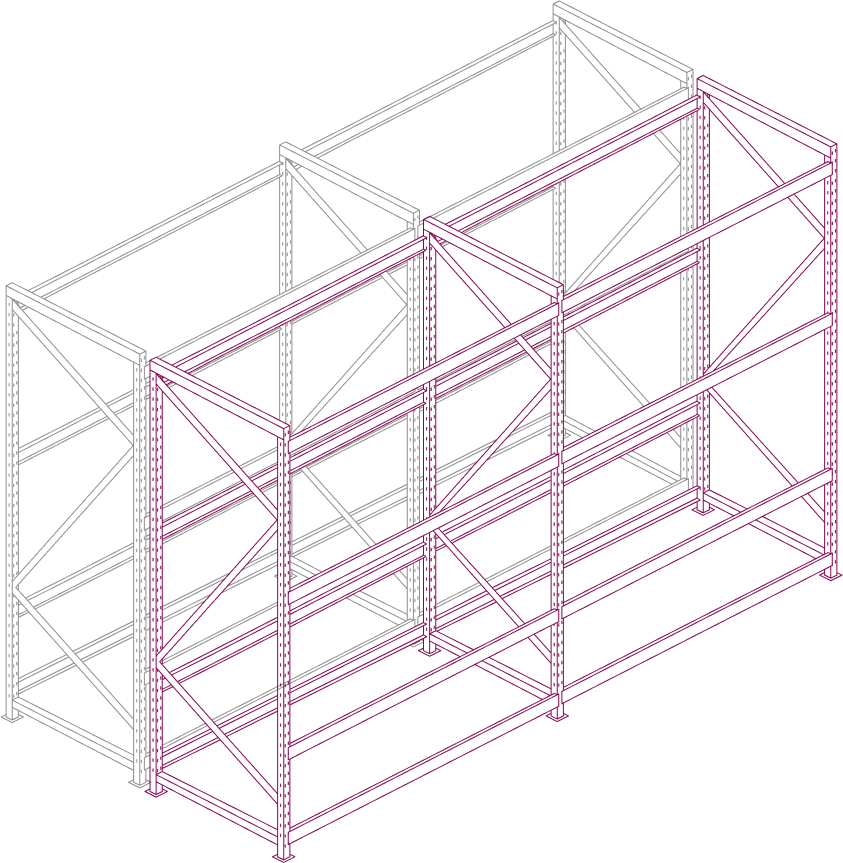

We provide full project management of high bay, in-rack, and exit/emergency lighting for all types of rack systems, including multi-level rack systems. This includes identifying lighting placement as well as electrical and lighting installation.

01 Lighting System Evaluation and Permitting Support

02 Lighting System Procurement and Installation

Types of Warehouse Lighting Systems

High Bay Lighting

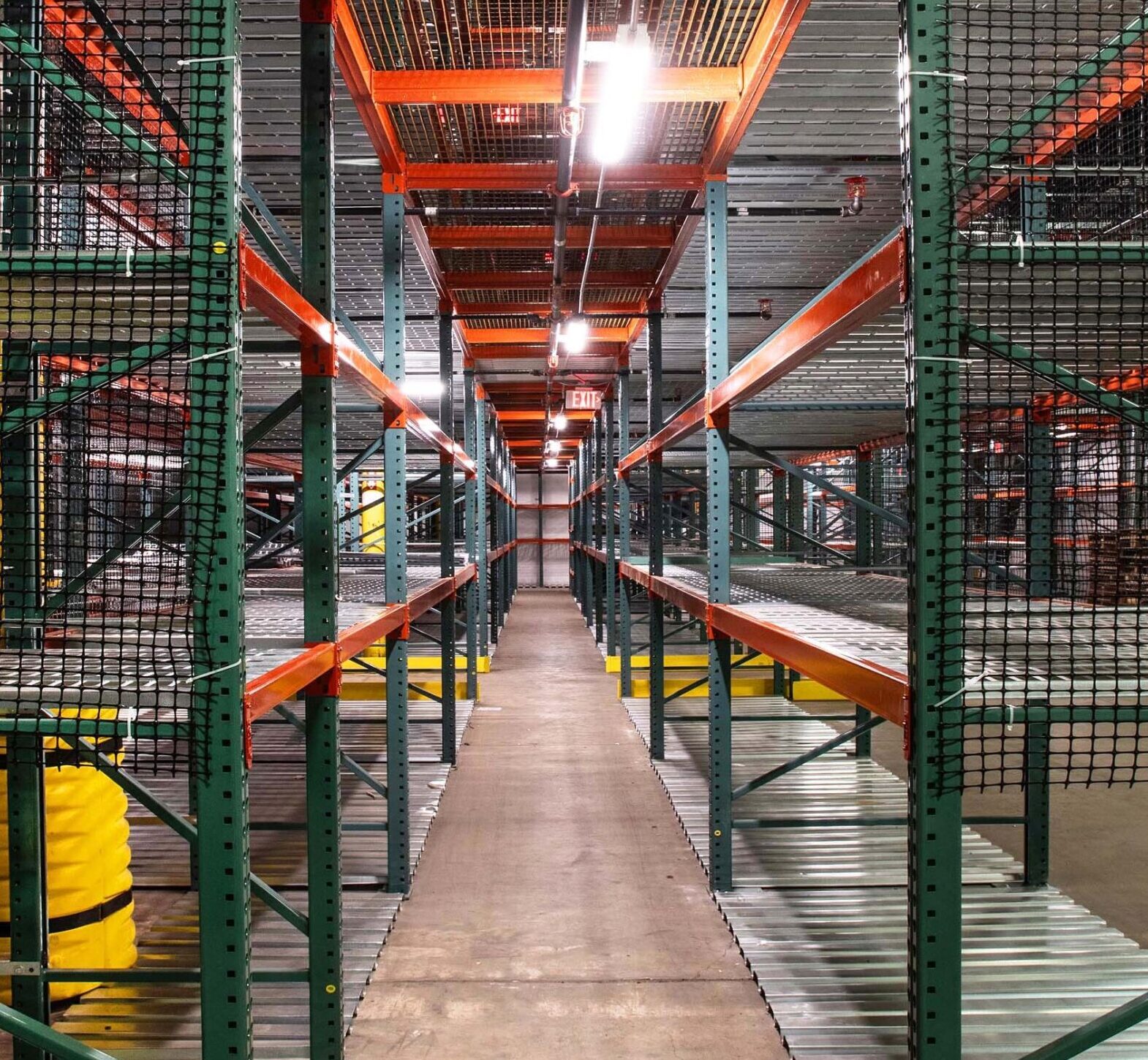

High bay lighting is mounted to the ceiling. These are typically channels of LED lighting. Oftentimes, we’ll attach high bay lighting on a chain so that it can hang down to better illuminate the aisles below.

High bay lighting is typically installed on the ceiling directly above each aisle. This ensures that the lighting will not get ‘drowned out’ by products before reaching the floor level.

In-Rack Lighting

In-rack lighting is essential for multi-level material handling systems. It ensures employees can adequately navigate a dense multi-level system. However, there are applications for in-rack lighting within a traditional rack system.

RCS uses LED channels for in-rack lighting that are tailored to this dense space. These channels are typically installed on the grating above all main aisles and catwalk aisles.

Exit and Emergency Lighting

Exit and emergency lighting is an essential part of the life safety requirements for a warehouse. For example, if power is lost due to weather or other hazards, employees must be able to exit the warehouse quickly and safely.

RCS provides all exit and emergency lighting necessary within a warehouse. We will identify all exit and emergency lighting required through our evaluations.

Warehouse Lighting Activation Options

There are several options available for

activation of high bay and in-rack lighting.

01 Motion and Heat Sensors

02 Traditional Switches

03 Push Button Timer

We provide our lighting services for all types of rack systems

Including selective rack, gravity flow rack, push back rack, drive-in rack, and multi-level systems.

For existing buildings

For new buildings

Warehouse Lighting

with RCS it’s easy

01 Step One

An RCS expert will determine where all lighting should be located based on CADD drawings of your warehouse and material handling system.

We will provide this information to all applicable parties to have this included in the CADD drawings.

02 Step Two

If desired, we will provide a full life safety evaluation to determine if a high pile storage permit is required. If required, we can provide a high pile storage drawing containing all life safety information, including exit and emergency lighting information. This is then submitted to the municipality for approval.

03 Step Three

Once all drawings are completed and all required permits are obtained, RCS engineers will source lighting from our network of approved vendors based on requirements and cost. We’ll work with all necessary parties to install these.

RCS is a team of experts who

are well versed warehouse lighting integration

161

Combined years of experience project managing material handling systems

243

Combined years of experience engineering material handling systems

373

Combined years of experience implementing material handling system safety regulations

Frequently Asked Questions

Are You in Need of Warehouse Lighting?

RCS provides full project management of high bay, in-rack, and exit/emergency lighting systems for warehouses. We offer all types of lighting, including energy-efficient sensor lighting.

Contact RCS for more information. We work with end users, manufacturers, dealers, and contractors.

Our team will be happy to help you better understand our services and provide you with a quote.

Call us at (630) 247-6934 or email at info@rcscorp.com.