How Do Fire Sprinklers Work: Each Part Explained

Contributing Author: Lori Palmer

An Introduction to How Fire Sprinklers Work

Warehouse fire sprinklers use a combination of heat detection and water distribution to suppress or extinguish fires. The basic principle behind their operation is to detect heat from a fire and activate a network of sprinklers to release water, cooling the flames and preventing the fire from spreading further.

Warehouse fire sprinkler systems are designed based on various factors, including the type of materials stored, the layout of the warehouse, and local fire safety codes. They are a critical component of fire safety in large commercial and industrial spaces, as they can help prevent catastrophic fires and protect lives and property. Regular inspection, maintenance, and testing are essential to ensure the proper functioning of these systems.

Here’s how they work in more detail:

- Heat Detection: Warehouse sprinkler systems typically use heat-sensitive devices called sprinkler heads. Each sprinkler head is equipped with a heat-sensitive element, usually a glass bulb or a fusible link. These elements are designed to respond to specific temperature thresholds.

- Temperature Thresholds: The temperature at which a sprinkler head activates depends on the design and intended use of the system. When the air temperature in the vicinity of a sprinkler head rises to the activation temperature, the heat-sensitive element reacts.

- Activation: When the heat-sensitive element reaches its activation temperature, it triggers the sprinkler head to allow water to flow.

- Water Flow: Once a sprinkler head is activated, water flows from the connected water supply pipe through the open sprinkler head. The water is under pressure, so it sprays out forcefully in a specific pattern to cover a designated area.

- Fire Suppression: The released water cools the surrounding environment, including the flames and the hot gases produced by the fire. This cooling effect reduces the heat energy and can often extinguish the fire or at least control it until firefighters arrive.

- Individual Activation: Warehouse sprinkler systems are designed with individual sprinkler heads that activate independently. Only the sprinkler head(s) directly exposed to the heat of the fire will activate, minimizing water damage to the rest of the warehouse.

- Alarm System: Many warehouse fire sprinkler systems are connected to fire alarm systems. When a sprinkler head activates, it can trigger an alarm to alert occupants and emergency responders to the fire.

The Components of a Fire Sprinkler System

There are two types of flue spaces: transverse and longitudinal.

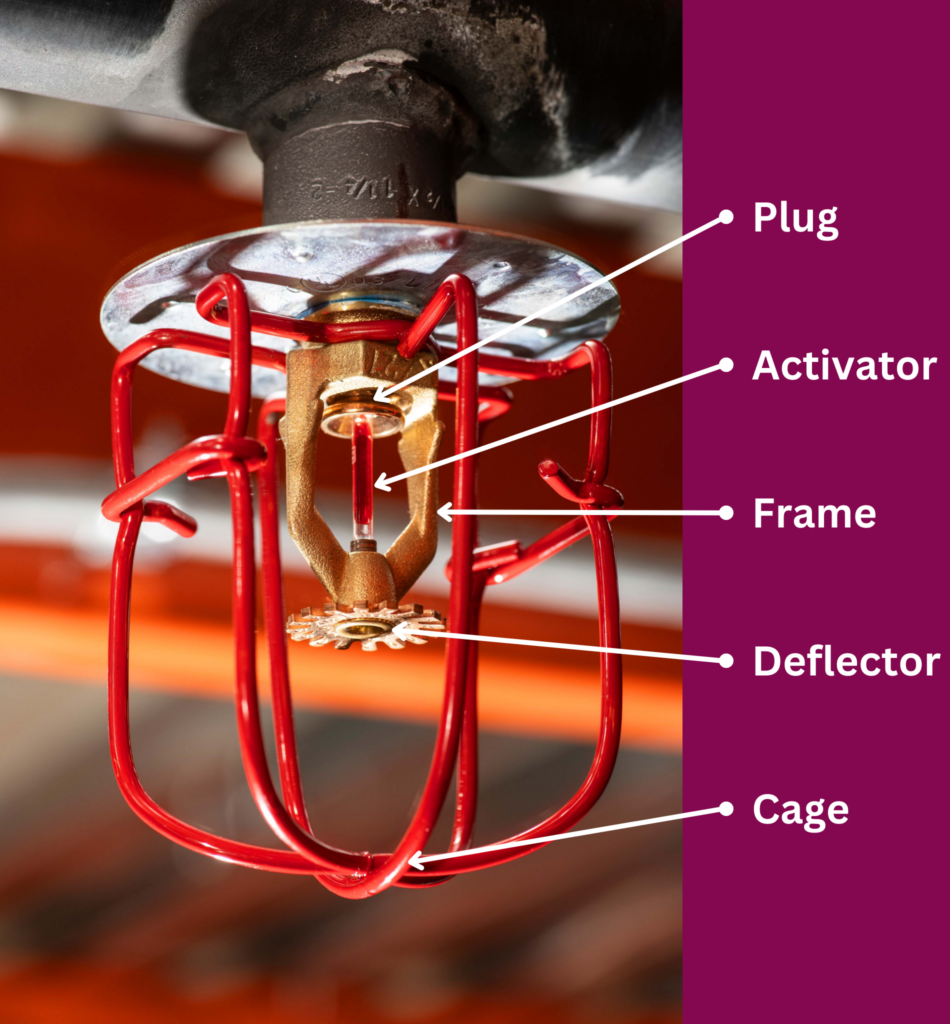

Fire Sprinkler Heads

Fire sprinkler heads consist of several parts that help effectively disperse water. These parts include activators, plugs, deflectors, frames, and cages.

The activator is a heat sensor that signals the release of water. Once it reaches its heat threshold, the activator will trigger the water flow via the plug. The plug is often fusible links or glass bulbs filled with heat-sensitive liquid, which are located within each sprinkler head. In the case of a glass bulb, it shatters due to the expanding air inside when heated, allowing water to flow. In a fusible link design, the link melts, releasing a valve that allows water to flow.

The deflector is the fan-shaped part that is fixed to the bottom of the sprinkler head. The deflector disperses water evenly to surrounding areas. Keeping all parts together is the frame of the sprinkler head. This is a metal structure that secures all parts together.

Cages are often included for protection of the sprinkler head. The cage is placed around the sprinkler head to ensure that it won’t be damaged, which can cause the sprinkler head to malfunction in the event of a fire.

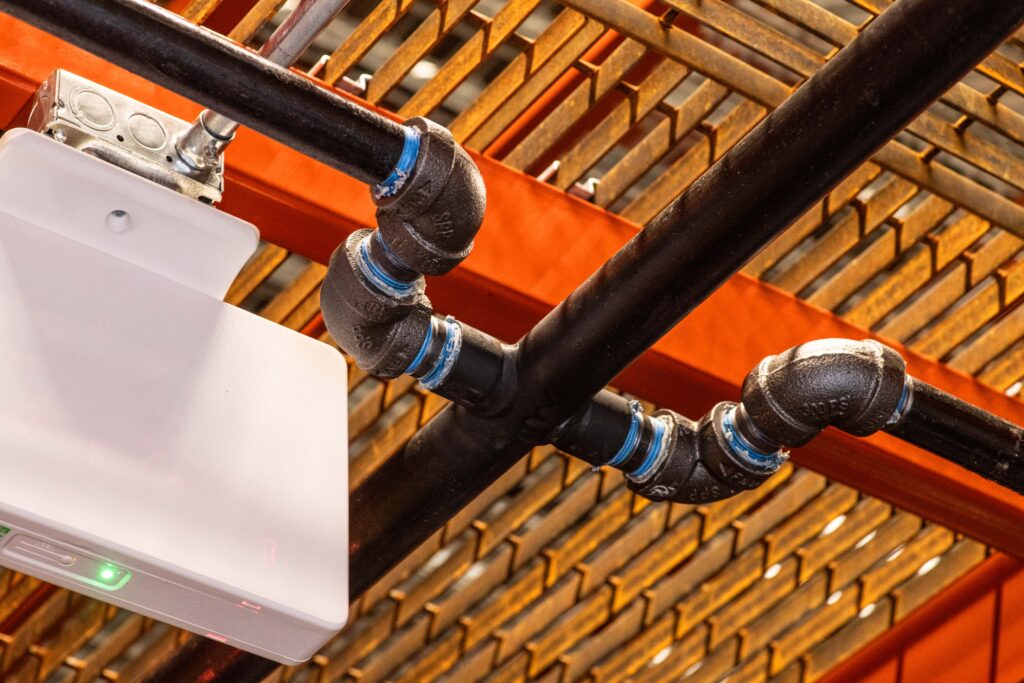

Pipes and Valves

A network of pipes connects the sprinkler heads to the water supply. These pipes transport water to the sprinkler heads, ensuring even coverage of the protected area. Warehouses in remote areas or with unreliable municipal water supplies may have dedicated water storage tanks to ensure a continuous water source for the sprinkler system.

When the system is not active, a stop valve is in place to ensure that the water doesn’t flow. A control valve is used to regulate the flow of water through the sprinkler system. It is typically located near the water supply connection and can be manually or electronically controlled.

Fire Alarm System

A fire alarm system is essential to alert occupants and emergency responders when the sprinkler system is activated. It can include audible alarms, visual alarms, and communication systems to notify authorities.

Fire Sprinkler Codes and Regulations

Fire sprinkler codes and regulations for warehouses are typically established by national and local building and fire code authorities. These codes and regulations are designed to ensure the safety of occupants, protect property, and minimize the risk of fire-related incidents. It’s important to note that codes and regulations can vary by location, so it’s crucial to consult with experts to ensure compliance with the specific requirements in your area. Common fire sprinkler codes and regulations for warehouses include:

- NFPA-13: Standard for the Installation of Sprinkler Systems: NFPA provides requirements for the design, installation, and maintenance of automatic fire sprinkler systems, including those in warehouses.

- International Building Code (IBC): The IBC is widely adopted in the United States and includes provisions related to fire sprinkler systems in warehouses. It often references NFPA standards for specific requirements.

- Local Building Codes and Ordinances: Many jurisdictions have their own building codes and ordinances that include specific requirements for fire sprinkler systems in warehouses. These requirements can vary significantly from one location to another.

- Commodity Classification: Warehouses are typically classified based on their contents and use, such as high-piled storage, rack storage, or general storage. The classification can affect the sprinkler system design and installation requirements.

Procurement and Compliance of Warehouse Fire Sprinklers With RCS

RCS is a team of experts that thoroughly understand the requirements of warehouse fire sprinklers. We offer full project management for ceiling-mounted and in-rack sprinkler systems.

We provide life safety evaluations, in which an RCS expert will determine where all sprinklers should be located to satisfy local municipality requirements. We will provide this information to all applicable parties to have this included on the CADD drawings. We will also submit all necessary drawings and other documentation needed to the municipality for approval. To learn more about our fire sprinklers, visit our warehouse sprinkler systems page.

Contact RCS for Fire Sprinklers for Your Warehouse

If you require ceiling mounted or in-rack fire sprinklers for your warehouse, contact RCS today.

RCS is a woman owned and operated, WBE certified company that specializes in making sure your material handling system is safe and code compliant. Our team consists of industry veterans, all who have extensive experience in warehouse fire code compliance, lighting requirements, installation, and rack safety.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Email us or call us at (630) 247-6934 to get in touch with an RCS expert.

About RCS

Contact our Experts

to get more information