Flue Spaces 101: A Guide to the Different Types & Benefits

Contributing Authors: Joe Kane and Lori Palmer

What are Flue Spaces?

Flue spaces are defined by the National Fire Protection Association (NFPA) as clear vertical lines of sight from the floor up to the ceiling within rack storage systems. The standards regarding flue spaces within a rack system can be found in NFPA 13: Standard for the Installation of Sprinkler Systems.

Flue spaces are a requirement within rack systems. These spaces provide two main benefits in the event of a fire within the rack system:

- Decreases the amount of time it takes for heat to ventilate upward to activate the sprinkler system.

- Decreases the amount of time it takes for water from the sprinkler system to penetrate down throughout the racking system.

Types of Flue Spaces

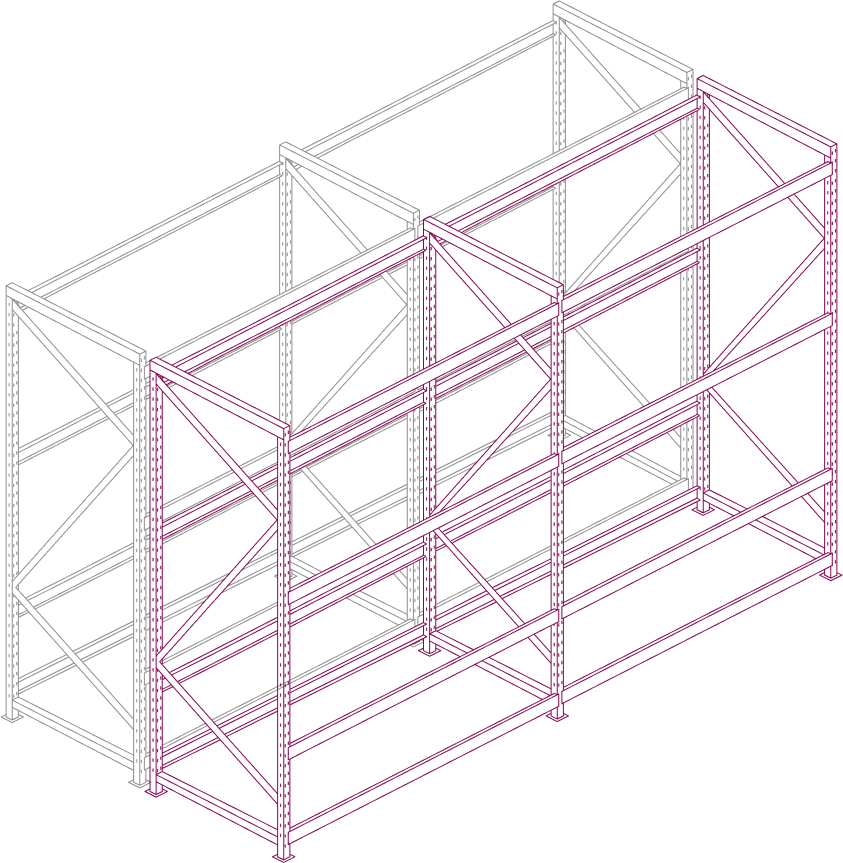

There are two types of flue spaces: transverse and longitudinal.

Transverse Flue Spaces

Transverse flue spaces run along the depth of each bay. Transverse flue spaces must be maintained unobstructed for the entire storage height and for the entire depth of the racking. If there are no obstructions across the entire width of the rack uprights, it is part of the transverse flue space.

Nominal 6” transverse flue spaces are required at rack uprights and between storage loads for single-, double-, and multi-row racking systems. Transverse flue spaces at uprights typically run along each side of the upright with each space being a minimum of 3”, creating a combined total of a 6” space (3” on each side of the upright). Alternatively, a 6” flue space can be maintained on one side of the upright. Transverse flue spaces between the storage loads shall be the full 6”.

Longitudinal Flue Spaces

Longitudinal flue spaces run the length between two back-to-back bays. NFPA requires this space to be 6” wide, though local municipalities may require larger spaces. Longitudinal flue spaces are always required for rack systems more than 25’ high. However, it can also be required for rack systems lower than 25’ if they are storing certain commodities, such as hazardous materials.

Importance of Pallet Rack Flue Space in Warehouses

Maintaining flue spaces in a warehouse to mitigate the damaging effects of a fire is highly important. Therefore, to build a material handling system, flue spaces must be present on the drawings submitted to the fire marshal or other fire code official.

In addition, flue spaces are required to be noted in a high pile storage report. A high pile storage report is a set of drawings that include analysis of all life safety and fire protection requirements as laid out by industry codes and standards. This is put together to obtain a high pile storage permit, which many municipalities require to operate a material handling system. A professional life safety evaluation of your material handling system can determine if a high pile storage report is required, and if so take all necessary steps to obtain this permit.

Over time, flue spaces can be disregarded by those loading the rack and become blocked by stored materials. It’s important to be aware that flue spaces must be maintained throughout the entire life of the material handling system to ensure protection against fire damage. To make sure flue spaces are being maintained, some municipalities allow fire inspectors to enter a building at any time to verify that the flue spaces are present. If they find that flue spaces are obstructed, a penalty will be issued at the discretion of the fire marshal or fire code official. This can range from a warning, a fine, or requiring the warehouse to shut down operation until flue spaces are once again present.

How to Maintain Flue Spaces in Racks

Fortunately, there are products that can be integrated into a rack system to ensure that flue spaces are maintained.

Fortunately, there are products that can be integrated into a rack system to ensure that flue spaces are maintained.

- Row spacers can be used to ensure that the longitudinal flue space requirement is adhered to. Row spacers are bolted onto uprights. They connect back-to-back rows of uprights, allowing for consistent spacing. When installing row spacers, it’s important to consider if your pallets hang over the back beam. If so, the row spacer should be long enough to accommodate the longitudinal flue space requirement beyond the pallet overhang.

- Load stop beams help to maintain longitudinal flue spaces by prohibiting pallets from being pushed farther over the back beam than planned. This helps to avoid obstructing the longitudinal flue space. If pallets do hang over the back beam, pallet stops are made to accommodate this, but they prohibit them from going any further. Longitudinal flue space should be accommodated for between the end of each overhang. Load stops are made of steel and are typically bolted onto the upright.

- Flue Keepers are designed in accordance with NFPA standards and are commonly used as a solution to maintain transverse flue spaces. Flue Keepers are steel rods that are bolted onto each side of the upright and span the depth of the upright. Once installed, they ‘block off’ a 3” space on each side of the upright. Additionally, Flue Keepers have an option to block off a 6” space, to be used on one side of an upright.

Contact RCS for Material Handling System Code Compliance and Safety Services

If you have concerns about flue spacing in your warehouse storage system, contact RCS today.

RCS is a woman owned and operated, WBE certified company that specializes in making sure your material handling system is safe and code compliant. Our team consists of industry veterans, all who have extensive experience in warehouse fire code compliance, lighting requirements, installation, and rack protection.

Our services include warehouse racking permit support, warehouse lighting systems, warehouse sprinkler systems, pallet rack protection, pallet rack repair, pallet rack safety inspections, and pallet rack installation.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Email us or call us at (630) 247-6934 to get in touch with an RCS expert.

About RCS

Contact our Experts

to get more information