Rack Safety Inspections

Ensure the safety of employees and

products in a distribution center.

Learn about

Rack Safety Inspections

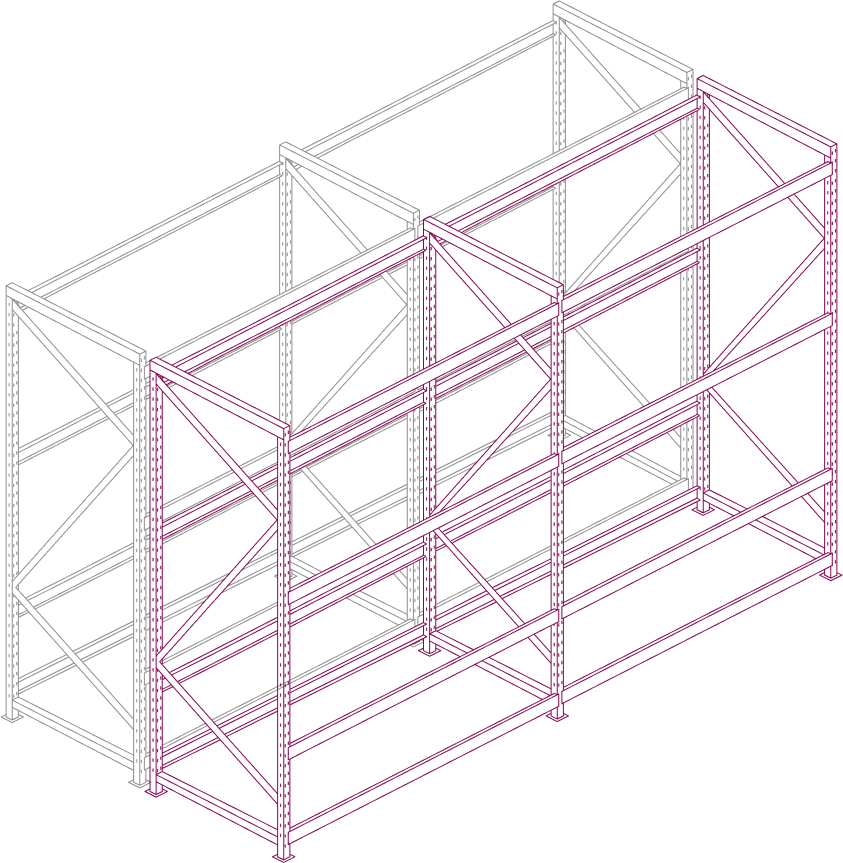

Rack damage and other rack safety concerns accumulate in a rack system overtime. This is concerning, since even damage that is not obvious can lead to a rack collapse. Because of this, professional rack safety inspections are an essential part of keeping your employees and assets safe.

RCS is a woman owned and operated, WBE certified company that provides professional rack safety inspections. Through these inspections we ensure that your system complies with all rack safety regulatory requirements.

RCS has a team of rack safety specialists. Our knowledge and experience allow us to analyze a rack system, locate all possible risks, and make suggestions to help you increase employee safety and asset protection.

Code Compliant Rack Safety Inspections

The goal of REB Contracting Solutions’ rack safety inspections is for you to comply with all regulatory requirements. These requirements are set forth by the American National Standards Institute (ANSI) and the Rack Manufacturer’s Institute (RMI).

The following regulations can be found in ANSI/RMI 16.1:

01 Repair and Replacement

of Damaged Components

02 Owner Maintenance

03 Additions, Alterations, and

Reconfigurations

04 Rack Damage

RCS Rack Safety

Inspection Process

01 Step One

The first step in our rack safety inspection process is for one of our rack safety experts to come to your location and perform a full walkthrough of your rack system. During this walkthrough, we’ll assess every part of your rack system for safety concerns. We record every instance of concern.

02 Step Two

A couple weeks following your assessment, we’ll provide you with a scope drawing. This scope drawing identifies each location of a safety concern and what type of concern it is. We’ll go through this drawing with you to explain all the safety concerns found and our recommendations to correct them.

03 Step Three

We can then provide you with a proposal for these remediation services.

More about our rack safety inspection process.

01 Types of Rack Damage

That Are Evaluated

02 Repairing Damaged Rack

03 Providing Subsequent Professional Rack Safety Inspections

RCS is a team of experts who

are well versed in Rack

Safety Inspections

161

Combined years of experience project managing material handling systems

243

Combined years of experience engineering material handling systems

373

Combined years of experience implementing material handling system safety regulations

Contact RCS for a Professional Rack Safety Inspection

If you’re concerned about the safety of your rack system, contact RCS to schedule a professional inspection of your rack system.

Contact RCS for more information. We work with end users, manufacturers, dealers, and contractors.

Our team will be happy to help you better understand our services and provide you with a quote.

Call us at (630) 247-6934 or email at info@rcscorp.com.